- On sale!

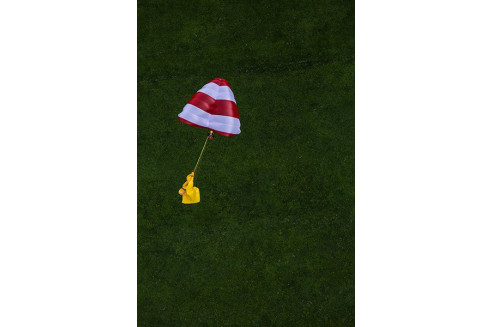

Beamer 3 airship parachute

404311092024

€975.00

Tax included

The new Beamer 3 is an update of the previous one, with improvements to the design but retaining its main features.

__ETS_EMBED_MA==__

Beamer 3 : 18 years of maximum security.

(round) conventional; the Beamer 3 sets new records in EN homologation tests.

The Beamer 3 builds on the best features of the Beamer 2, with a completely redesigned strap system that improves setup, operation, and installation. The legend continues.

The four most important features of the Beamer 3:

Quick opening

Opening time is the most important criterion for a reserve parachute. If the reserve parachute needs to be pulled at low altitude—and this is a common situation—a second can be crucial. The Beamer 3's unique shape and special folding technique allow it to open up to 50% faster than a PDA parachute.

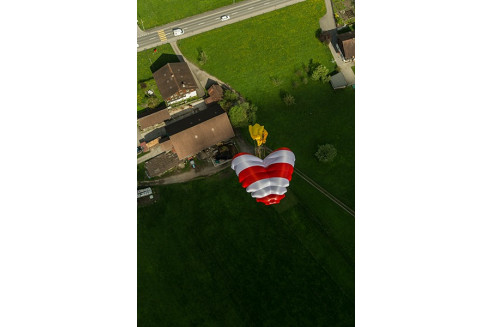

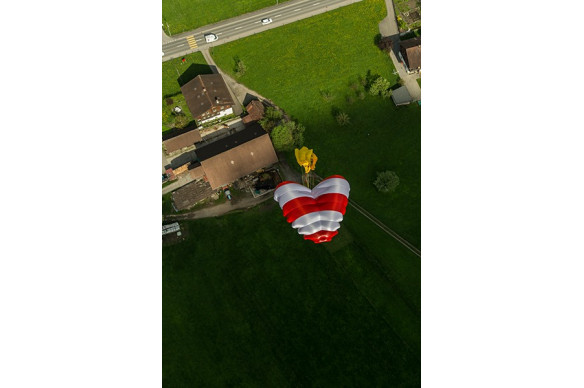

Stability after opening

When developing a Rogallo-type parachute, the main concern is how it interacts with the glider. After opening, the glider can become stuck (the typical situation, without a quick-release system). This is where the Beamer 3 excels and is far superior to the smaller models available on the market. After a rapid opening, the Beamer 3 quickly takes control, beginning to fly forward very slowly, thus preventing the glider from intervening. The Beamer 3 achieves its stability, among other reasons, from its low wing loading. This goes hand in hand with our basic recommendation: "Don't trust anything under 40 square meters."

As a special feature, we developed the "braked deployment" for the parachute—successfully applied on the Beamer 2. This results in a lower horizontal speed and provides what most pilots need: the advantages of the vertical travel of a round parachute (PDA type) with the advantage of a Rogallo (airship). For example, when deploying the Beamer next to a vertical rocky cliff, or in strong wind conditions, its initial descent will be almost vertical. Then, by activating the control lines, its horizontal speed can be utilized, and if the pilot has enough altitude, he can avoid the Beamer 3 away from danger (rocks, buildings, cables, etc.).

The "delayed opening" automatically and effectively prevents another dangerous effect, known as "downplaning." This occurs when the paraglider and parachute enter a mirror-like configuration, pulling on each other and thus increasing the descent speed and increasing the chance of an accident. The "delayed opening" system and the Beamer 3's large surface area prevent this situation.

Low rate of decline

The next most important consideration, once the parachute is deployed and stable, is the descent rate. Low wing loading and modest horizontal speed give the Beamer 3 a low descent rate unmatched by its competitors. EN certification bodies have confirmed a Beamer 3 descent rate of 3.9 m/s at full load (130 kg, without the glider). With the braking effect of the glider, the rate is reduced to 3.0 m/s.

Handling and horizontal flight, the Beamer's specialty!

In real-life parachute launch conditions , the paraglider can severely complicate the situation. In many cases, it's during and after deployment, and therefore doesn't fly. In this situation, descending with the Beamer 3 is a pleasure. The parachute reacts immediately to steering and descends as slowly as possible.

When releasing the reserve while the glider is in flight, as is normal during SIV training, the descent rate of any parachute can be affected. If the glider reopens during descent, it can be deflated using B-risers or by retracting it completely. This will improve the steerability of the parachute. Numerous examples from practice launches confirm the excellent performance of Beamers in all situations.

Paragliders tangled in parachute lines: in this situation, a pilot with a quick-release system will appreciate the qualities of the Beamer 3. When the glider is released, gliding performance is doubled with a slight detriment to the descent rate .

Quick-release systems make sense in competition (risk of collisions) and for Acro. A strap cutter secured with a long bungee cord will do the same in an emergency.

Technical differences and similarities between the Beamer 3 and the Beamer 2

The Beamer 3 features a completely new, user-friendly riser system. It reduces the possibility of twist and makes parachute deployment easier. Parachute packing personnel will appreciate the following: the reduced control lines for the "braked opening" phase are easy to understand. The risers are designed for shoulder-level deployment. Short extensions are required for parachutes installed in frontal containers.

The size, profile, lines and flight behavior remain identical to the Beamer 2. New construction details and new risers reduce the weight from a "light" 1,950 g to a very light 1,785 g for an area of 42 m2.

After three years of positive experiences with the Beamer 2, we can assume the same performance for lines and fabric. Despite its lightweight construction, the Beamer 3 is robust and durable and can be cast on water.

Check out the Beamer 3 Light (only 1,370 g): lighter than the Beamer 2 by more than half a kilo.

When developing a Rogallo-type parachute, the main concern is how it interacts with the glider. After opening, the glider can become stuck (the typical situation, without a quick-release system). This is where the Beamer 3 excels and is far superior to the smaller models available on the market. After a rapid opening, the Beamer 3 quickly takes control, beginning to fly forward very slowly, thus preventing the glider from intervening. The Beamer 3 achieves its stability, among other reasons, from its low wing loading. This goes hand in hand with our basic recommendation: "Don't trust anything under 40 square meters."

As a special feature, we developed the "braked deployment" for the parachute—successfully applied on the Beamer 2. This results in a lower horizontal speed and provides what most pilots need: the advantages of the vertical travel of a round parachute (PDA type) with the advantage of a Rogallo (airship). For example, when deploying the Beamer next to a vertical rocky cliff, or in strong wind conditions, its initial descent will be almost vertical. Then, by activating the control lines, its horizontal speed can be utilized, and if the pilot has enough altitude, he can avoid the Beamer 3 away from danger (rocks, buildings, cables, etc.).

The "delayed opening" automatically and effectively prevents another dangerous effect, known as "downplaning." This occurs when the paraglider and parachute enter a mirror-like configuration, pulling on each other and thus increasing the descent speed and increasing the chance of an accident. The "delayed opening" system and the Beamer 3's large surface area prevent this situation.

Low rate of decline

The next most important consideration, once the parachute is deployed and stable, is the descent rate. Low wing loading and modest horizontal speed give the Beamer 3 a low descent rate unmatched by its competitors. EN certification bodies have confirmed a Beamer 3 descent rate of 3.9 m/s at full load (130 kg, without the glider). With the braking effect of the glider, the rate is reduced to 3.0 m/s.

Handling and horizontal flight, the Beamer's specialty!

In real-life parachute launch conditions , the paraglider can severely complicate the situation. In many cases, it's during and after deployment, and therefore doesn't fly. In this situation, descending with the Beamer 3 is a pleasure. The parachute reacts immediately to steering and descends as slowly as possible.

When releasing the reserve while the glider is in flight, as is normal during SIV training, the descent rate of any parachute can be affected. If the glider reopens during descent, it can be deflated using B-risers or by retracting it completely. This will improve the steerability of the parachute. Numerous examples from practice launches confirm the excellent performance of Beamers in all situations.

Paragliders tangled in parachute lines: in this situation, a pilot with a quick-release system will appreciate the qualities of the Beamer 3. When the glider is released, gliding performance is doubled with a slight detriment to the descent rate .

Quick-release systems make sense in competition (risk of collisions) and for Acro. A strap cutter secured with a long bungee cord will do the same in an emergency.

Technical differences and similarities between the Beamer 3 and the Beamer 2

The Beamer 3 features a completely new, user-friendly riser system. It reduces the possibility of twist and makes parachute deployment easier. Parachute packing personnel will appreciate the following: the reduced control lines for the "braked opening" phase are easy to understand. The risers are designed for shoulder-level deployment. Short extensions are required for parachutes installed in frontal containers.

The size, profile, lines and flight behavior remain identical to the Beamer 2. New construction details and new risers reduce the weight from a "light" 1,950 g to a very light 1,785 g for an area of 42 m2.

After three years of positive experiences with the Beamer 2, we can assume the same performance for lines and fabric. Despite its lightweight construction, the Beamer 3 is robust and durable and can be cast on water.

Check out the Beamer 3 Light (only 1,370 g): lighter than the Beamer 2 by more than half a kilo.

| Beamer 3 Technical Data | M | S | M light | S light |

| Flat area: | 41.75m2 | 35.47 m2 | 41.75m2 | 35.47 m2 |

| Weight with inner container: | 1835g | 1640 g | 1420 g | 1230 g |

| Front mount extension kit: | 20g | 20g | 20g | 20g |

| Maximum flight weight: | 130kg | 90 (100) * kg | 130kg | 90 (100) * kg |

| Sink rate at 130 kg (free from the glider EN test): | 3.8m/sec | 3.7 m / sec | 3.8m/sec | 3.7 m / sec |

| Time (tested EN) Opening: | 2 sec | 2 sec | 2 sec | 2 sec |

| Volume Value: | 4959ccm | 4432 cc | 3837 cc | 3324 cc |

| Number of panels: | 18 | 13 | 18 | 13 |

| Number of lines: | 9x2 | 8x2 | 9x2 | 8x2 |

| Certification number: | EP 073.2013 / 073.2013 RG | EP / RG 102.2013 | EP / RG 101.2013 | EP / RG 104.2013 |

| Applied test guidelines/standards: | EN 12491:2001 / 2.DV LuftGerPV § 1, Nr.7c | EN 12491:2001 / 2.DV LuftGerPV § 1, Nr.7c | EN 12491:2001 / 2.DV LuftGerPV § 1, Nr.7c | EN 12491:2001 / 2.DV LuftGerPV § 1, Nr.7c |

- Homologación Paracaidas

- Norma EN máximo - 5,5m/sg a carga máxima

- Forma

- Triangular, tipo rogallo

- Tallas disponibles

- 100 - 130 - 170

- Carga máxima homologada

- 100 kg

130 kg

170 kg

No reviews

You might also like

.jpg)